Description

Bambu Lab H2S – Specifications

-

Printing Technology: Fused Deposition Modeling (FDM)

-

Build Volume: 340 × 320 × 340 mm³

-

Printer Dimensions: 492 × 514 × 626 mm³

-

Net Weight: 30 kg

-

Frame & Body: Aluminum and Steel Chassis, Plastic & Glass Outer Frame

Toolhead & Extruder:

-

Extruder Gear & Nozzle: Hardened Steel

-

Max Nozzle Temperature: 350 °C

-

Included Nozzle: 0.4 mm

-

Supported Nozzle Sizes: 0.2 mm, 0.4 mm, 0.6 mm, 0.8 mm

-

Filament Diameter: 1.75 mm

-

Motor: High-precision Permanent Magnet Synchronous Motor

-

Built-in Filament Cutter

Heatbed & Build Plate:

-

Max Heatbed Temperature: 120 °C

-

Build Plate: Flexible Steel Plate

-

Included: Textured PEI Plate (supports smooth PEI plate)

Speed & Flow:

-

Max Print Speed: 1000 mm/s

-

Max Acceleration: 20,000 mm/s²

-

Max Flow Rate: 40 mm³/s

Chamber & Air System:

-

Active Heated Chamber: Up to 65 °C

-

Filtration: G3 Pre-filter, H12 HEPA, Granulated Coconut Shell Carbon Filter

-

Air Purification: VOC & Particulate Filtration

Material Compatibility:

PLA, PETG, TPU, PVA, BVOH, ABS, ASA, PC, PA, PET, PPS + Carbon/Glass Fiber Reinforced Composites

Sensors & Features:

-

23 Sensors, 3 Cameras (Live View, Toolhead, BirdsEye*)

-

Filament Runout & Tangle Sensors

-

Filament Odometry

-

Power Loss Recovery

-

Door Sensor

Electronics & Connectivity:

-

Display: 5-inch 720×1280 Touchscreen

-

Storage: 8 GB eMMC + USB Port

-

Control: Touchscreen, Mobile App, PC App

-

Network: Wi-Fi (2.4 GHz & 5 GHz), Ethernet not available

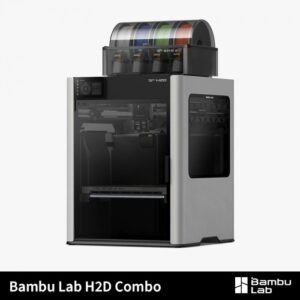

The Bambu Lab H2S is a high-performance 3D printer designed as a personal manufacturing hub, equipped with Bambu Lab’s second-generation 3D printing technology. Its proprietary servo motor extruder increases extrusion force by 67%, enabling ultra-fast printing speeds of up to 1000 mm/s with 20,000 mm/s² acceleration, without under-extrusion. The machine achieves motion accuracy under 50 μm thanks to its Vision Encoder, which automatically compensates for mechanical drift for lasting precision. With 23 sensors and 3 cameras, the H2S features full filament path AI detection, monitoring flow, temperature, and filament usage while detecting print failures like spaghetti and foreign objects. The sealed chamber recirculates filtered heated air for stable high-temperature printing of engineering parts and uses a top vent system for efficient low-temperature printing and fume control. The H2S boasts the largest build volume among Bambu Lab printers at 340×320×340 mm³, 120% larger than the X1C, and supports temperatures up to 350 °C on the hotend and 65 °C in the actively heated chamber. It is compatible with a wide range of materials including PLA, PETG, TPU, ABS, ASA, PC, PA, PET, PPS, and carbon/glass fiber-reinforced composites. Additional highlights include a hardened steel extruder gear, textured PEI build plate, 40 mm³/s max flow hotend, HEPA and carbon filtration, power loss recovery, multiple built-in cameras, and a 5-inch touchscreen interface with Bambu Studio software support. The optional H2S Laser Edition adds a 10W blue-light laser for cutting and engraving wood, leather, rubber, acrylic, and more, with safety features like flame detection, door sensors, and a safety key.

Reviews

There are no reviews yet.